The lime saturation factor LSF is a ratio of CaO to other oxides it is used to control the proportion of cement raw meal. The share of Portland Slag Cement in cement production remained flat at less than 10 over the same period.

Environmental Sustainability In Cement Industry An Integrated Approach For Green And Economical Cement Production Sciencedirect

The amount of natural resources fuel and raw.

Clinker factor in cement production. LC3 cements 5 have a clinker factor of only 50 with the rest being 30 calcined clay metakaolinite 15 limestone and 5 gypsum. The secondary reason is to reduce the environmental impact of. Clinker C3S C2S C3A C4AF Cement C3S C2S C3A C4AF Burnability index for clinker Burnability factor for clinker Burning temperature minimum.

Estimating emissions generally involves two emission factors. It is produced by heating limestone and clay to the point of liquefaction at about 1400C-1500C in the rotary kiln. The clinker factor reduced to 071 in 2017 from 074 in 2010.

It is responsible for 10 of the total production of Portland cement and 125 of clinker production in Turkey 12. Each 1 drop in clinker factor can reduce emitted CO 2 by 8-9 kgcement tonne. Reduction of specific.

In August 2018 the Global Cement and Concrete Association GCCA said it was taking over the work previously done by the CSI from 1 January 2019. Decrease of clinker factor in cement or improvement of cement quality. In the operation of the cement kiln the thermal system of.

While even in non-optimized conditions acceptable results have been achieved in terms of performance of the resulting material. In the inter-grinding mode with Clinker Slag Gypsum ground together the clinker with Gypsum gets preferentially ground leaving slag relatively coarser proper optimization of the distribution of slag in desired size fractions of Cement with or without cement additives could help achieve a clinker factor of around 35 to 40. Cement equivalent Cement equivalent is a cement production value which is determined from clinker produced on-site applying the plant specific clinkercement-factor.

The primary motivation is to reduce the energy consumption and CO 2 emissions associated with cement clinker production in rotary kilns. For example a 1 increase in SCM can reduce 28-day mortar strength by 02 - 08MPa depending on SCM type cement fineness grinding system and clinker characteristics. The incentive to reduce the clinker factor in cement products is two-fold.

In the process of clinker production strict control of these factors can ensure the production of high-quality high-yield clinker. It is generally accepted that the production of 1 t of ordinary Portland cement OPC creates over 800 kg of CO 2. Reducing the Clinker Factor by partially substituting the clinker used in the composite cement production process with materials that have binding properties also known as mineral components.

As the promoters of the technology state producing LC3 cement does not require capital intensive modifications to existing cement plants and produces binders with the same performance as OPC. The industrial trial to produce cement with a clinker factor of 50 at the industrial scale has proven that the new system is very robust. It can improve the cement fineness to 3848cm2gr and decrease the sieving R45μ to 10.

However increasing the SCM level to lower the clinker factor usually results in somewhat poorer cement performance. The lumps or nodules of clinker are usually of diameter 3-25 mm and dark grey in color. The production of clinker is the main source of CO 2 in cement production.

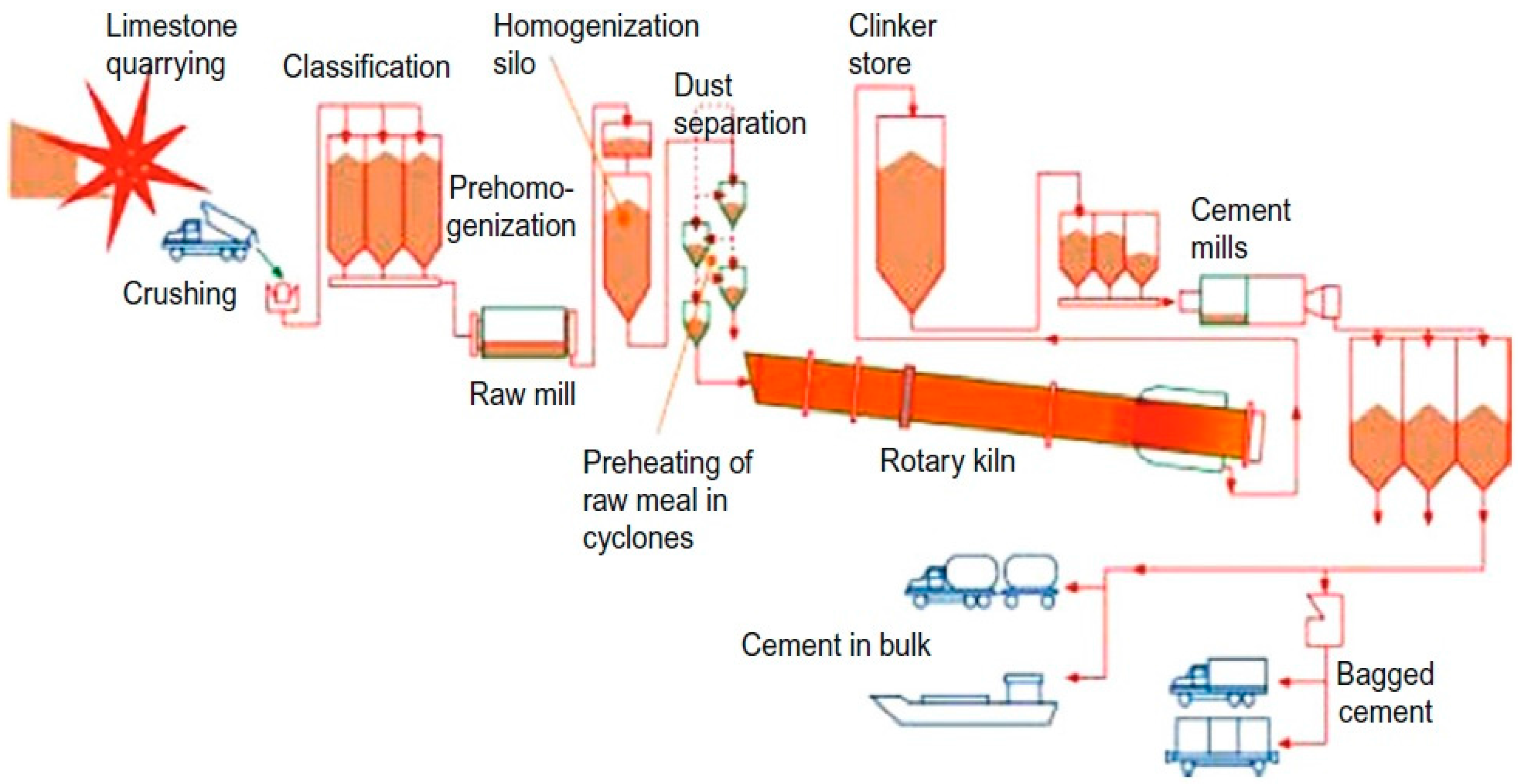

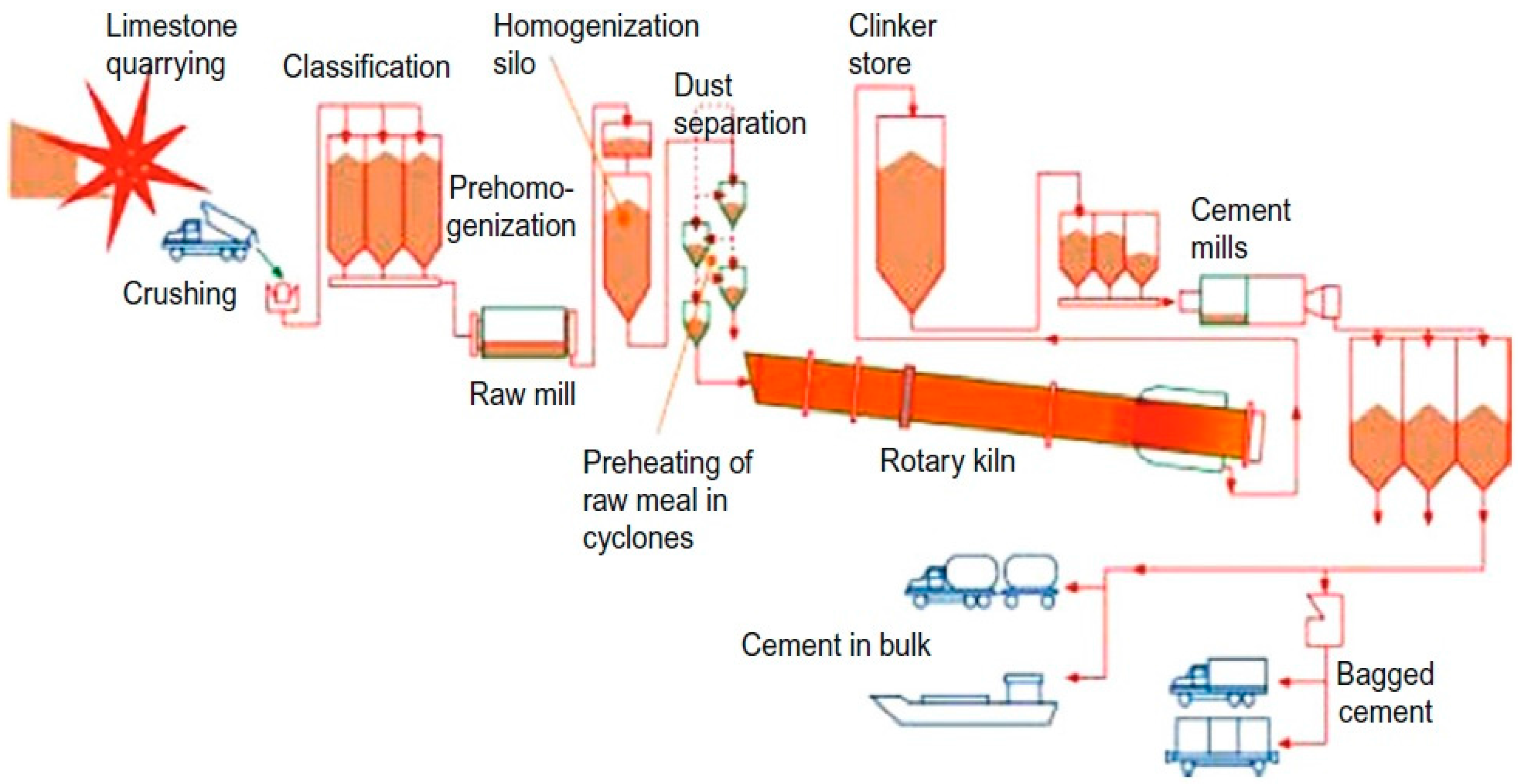

The process of the company is illustrated in Fig. Clinker is a nodular material produced in the kilning stage during the production of cement and is used as the binder in many cement products. Akçansa is a joint venture of Sabancı Holding and HeidelbergCement and is the leader in cement production in Turkey.

221 Clinker emission factor The clinker emission factor is the product of the fraction of lime in the clinker multiplied by the ratio of the mass of CO2 released per unit of lime. Increase of kiln throughput. Cement equivalent line021b.

In addition the strength of the cement produced is higher than the standard. Benefits of Clinker Mineralization. Reducing the Clinker Factor.

Lime Saturation Factor LSF is the ratio of the actual amount of lime in raw mealclinker to the theoretical lime required by the major oxides SiO 2 Al 2 O 3 and Fe 2 O 3 in the raw mix or clinkerIt is practically impossible to complete the reaction to 100 in a reactor like rotary kiln therefore there will always be some unreacted lime CaO f known as free lime. Reduction of burning zone temperature. The clinker factor varies from 783 to 729.

The results show that the optimal clinker factor is at 745 with the CGA addition 300 ppm. An emission factor for clinker production and an emission factor for Cement Kiln Dust CKD production. To reduce clinker factor in blended cement to add cementitious materials maximum permissible limit as per IS codes which will not only increase the life of the limestone deposits reduce the CO2 emission but also help in imparting higher durability potential to the structures.

The following are several important factors affecting the cement clinker quality.

Parameter Values For The Cement Manufacturing Process Download Table

Schematic Diagram Of Cement Production And Stationary Sources In The Download Scientific Diagram

Cement Training Course In Powerpoint Civil Engineering Engineering Programs Civil Engineering Software

Practical Advises To Save Costs In Your Cement Plant Complete Equipment Modification Very Important Infinity For Cement Equipment

The Cement Manufacturing Process

Fate Of Thallium During Precalciner Cement Production And The Atmospheric Emissions Sciencedirect

Energies Free Full Text Assessment Of Energy Performance And Emission Control Using Alternative Fuels In Cement Industry Through A Process Model Html

World Cement Production In 2016 By Region And Main Countries 4 65 Gt 4 Download Scientific Diagram

Co2 Emission Reduction In The Cement Industry By Using A Solar Calciner Sciencedirect

Https Www Mdpi Com 2071 1050 13 1 135 Pdf

Mass Balance For Cement Production Download Scientific Diagram

Scheme Of Cement Production Download Scientific Diagram

The Overall Input And Output Of Cement Production Download Scientific Diagram

Decarbonizing Cement Production Sciencedirect

The Overall Input And Output Of Cement Production Download Scientific Diagram

Cement Clinker Quality Control During Clinker Production Process Agico

Decarbonizing Cement Production Sciencedirect

Grey2green The Quiet Revolution In Cement Production Engineered